Do your students understand pasta and its intricacies? After all, 55% of Americans eat pasta regularly. Perhaps it is because it’s convenient, cooks easily or is economical, but most people eat this centuries-old ubiquitous food. But consuming a product and knowing a product are different ideas. That’s where culinary instructors swoop in and work their educational magic.

Do your students understand pasta and its intricacies? After all, 55% of Americans eat pasta regularly. Perhaps it is because it’s convenient, cooks easily or is economical, but most people eat this centuries-old ubiquitous food. But consuming a product and knowing a product are different ideas. That’s where culinary instructors swoop in and work their educational magic.

Taking a widely known application, such as linguine and sauce, and breaking it down into its simplistic parts before learning to correctly build the ingredients into the dish is what culinary instructors do. Here are resources to help create a lesson plan that will educate, inform and perhaps even surprise students with its complexity concerning making a familiar pasta dish.

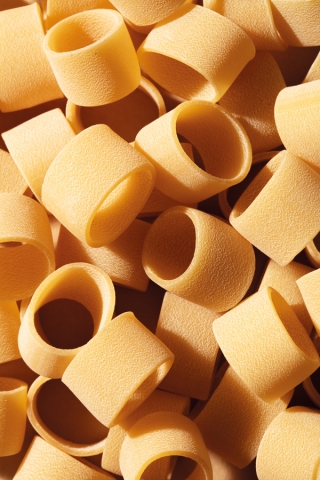

Die-cut texture or lack thereof

Pasta is a seemingly simple concoction of durum semolina flour and water formed into a dough and extruded through a die to create different shapes that are usually dried. The die determines the finished noodle’s texture.

Prior to the creation of Teflon in 1938, pasta dough was extruded through dies whose blades were made of bronze, widely considered one of the hardest and most durable metals. This process created pasta shapes with rough edges and course surfaces.

Pasta manufacturing companies for the most part quickly switched to using Teflon-coated dies once it became available. The slippery blade surfaces created pasta forms quicker because of reduced resistance. Additionally, according to Barilla Executive Chef Lorenzo Boni, Teflon-coated dies are less expensive to make and last longer. “They also make very consistent shapes because the surface is uniform, and the resulting pasta will be more durable as there are no marks or scoring from the die itself,” Chef Boni noted.

However, there is an important reason to consider going old-school and searching for bronze-cut pasta shapes and it’s something culinary students should know about: mouthfeel, texture and taste.

The bronze die-cut pasta shapes are more porous and hold the pasta sauce in place without letting it quickly slip down the noodles. Chef Boni agreed, “It is all about the taste experience. Bronze dies are rougher than Teflon, so they score the pasta as it’s extruded, making the starches in the pasta more available to be released. You can see this if you look closely, little white pock marks or scratches on the dried pasta surface.” Bronze-cut pasta absorbs sauce effectively, improving the mouthfeel and flavor of pasta dishes.

Chef Boni also noted that boiled water is different with pasta made from a bronze blade. “You will get starchier pasta water, which is gold for the chef in binding a sauce and making it creamy. The surface of the pasta will retain that starchiness too. This acts like a binding agent helping sauces cling to the pasta. For Barilla’s Al Bronzo (bronze-cut) pasta, we take this a step further and micro-engrave the die surface, enhancing that effect.”

Chef Boni also noted that boiled water is different with pasta made from a bronze blade. “You will get starchier pasta water, which is gold for the chef in binding a sauce and making it creamy. The surface of the pasta will retain that starchiness too. This acts like a binding agent helping sauces cling to the pasta. For Barilla’s Al Bronzo (bronze-cut) pasta, we take this a step further and micro-engrave the die surface, enhancing that effect.”

Both the bronze-cut and Teflon-cut processes can be utilized for fresh pasta as well.

Selecting the perfect shape and history

According to Colorado State University Associate Professor Jeffery Miller, there are at least 350 shapes of pasta available for sale. All pasta shapes broadly fit into these categories:

Long - Angel hair, fettuccine, fideo, fusilli, lasagna, lasagne, linguine, mafalda, pappardelle, reginette, spaghetti, tagliatelle, thin spaghetti, vermicelli

Tube - Bucatini, casarecce, cavatappi, elbow, manicotti, penne, penne mostaccioli, penne rigate, pipe rigate, pipette rigate, riccioli, rigatoni, tortiglioni, tubini, ziti

Soup - Acini de pepe, alphabet, ditalini, orecchiette, orzo, pastina

Stuffed - Ravioli, tortellini

Special shape - Anelli/anellini, campanelle, cappalletti, cavatelli, conchiglie, egg noodles, farfalle, farfalline, gemelli, gigli, radiatori, rocchetti, rotelle, rotini, ruote, tripolini

Click here for a chart of classic Barilla pasta names and shapes.

An additional resource for a culinary instructor’s pasta lesson may also include information from Barilla’s pasta encyclopedia. This guide details popular pasta shapes, how the names were derived as well the shape’s history.

For example, orzo is also known as risoni (big rice in Italian) and puntalette (tiny tips in Italian). Orzo translates into barley in Italian. Educators may be interested to know that ziti gets its name from zita or zito, in an Italian dialect, which translates to bride or groom. That’s because traditionally, in places like Naples, this smooth, hollow, tubular shape was reserved for special occasions such as banquets and weddings.

Sauce and shape for the perfect marriage

Another important pasta lesson aspect is selecting the correct sauce to meld with the pasta shape. Instructors know that in general, the larger pasta shapes with hollows and curves are best suited for thicker and heartier sauces, while thinner and more delicate strands are used for light oil-based or cream sauces. Some pasta shapes are regional and traditionally paired with a certain sauce or dish.

Twisted pasta shapes such as rotini and fusilli work well with heavier, more textured sauces like pesto or Bolognese, or those with ground meat or finely chopped vegetables. Smaller pasta such as orzo or elbows are best in soups, stews, or any recipe with extra sauce or liquid. Unlike longer pasta which break down quickly in surplus liquid and heat, smaller pasta keeps its shape.

Instructors teaching beginning culinary students can use the information in the Barilla Pasta Recipe Builders to help create a myriad of pasta dishes. These globally inspired templates guide students by selecting appropriate pasta shapes, building the sauce, adding protein and spices, and finishing with garnish.

Additional educational resources for a culinary instructors’ pasta lesson plan:

- New York Times article discussing the problems with Teflon-cut slippery noodles.

- A 2011 scientific paper titled, "Effect of Die Material on Engineering Properties of Dried Pasta," found that "extrusion with a bronze die induces the production of more porous and less dense pasta, but does not have an impact on pasta shrinkage and volumetric percentage of water lost replaced by air during drying."